Automated Blue Light disinfection in food industry

Despite strict regulatory requirements, the risk posed by pathogenic microbes such as listeria, salmonella, mold, and biofilms remains high and requires the use of significant resources and chemicals.

Spectral Blue MWHI® devices provide continuous bioburden control in food processing environments

Highest efficacy without residues

Spectral Blue MWHI® devices automatically and continuously combat the most common and critical pathogens found in food production every day.

- Spectral Blue leaves no chemical residue or harmful by-products.

- Spectral Blue does not corrode plastics and offers an environmentally conscious alternative to conventional methods.

- Spectral Blue poses no safety risks to your staff or food contact areas.

Automated, controlled and error-free

- Automation ensures that disinfection is performed in the same way every day and simplifies the monitoring of disinfection cycles.

- Compliance with global standards such as HACCP and ISO 22000 is facilitated.

Elimination of food germs and destruction of biofilms throughout the production environment.

Prevention of cross-contamination and false-positive results in food laboratories.

Reduce dependence on harmful chemical disinfectants and hazardous residues.

Spectral Blue MWHI® is your supplementary insurance for the uncompromising hygiene.

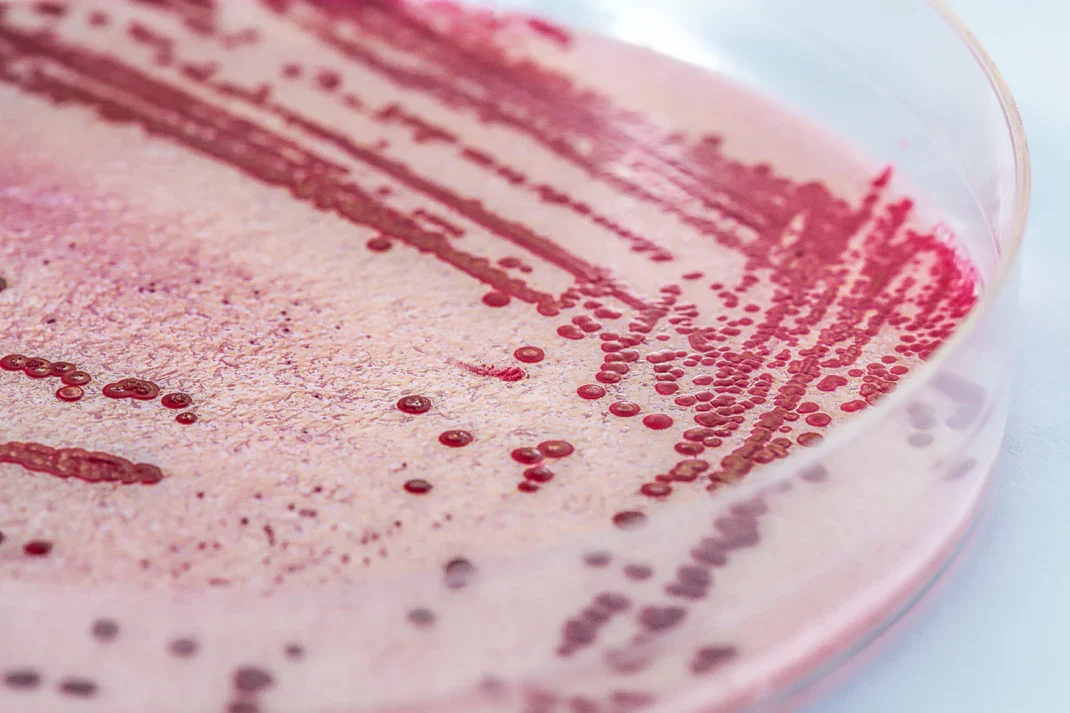

Listeria and Salmonella

Listeria and Salmonella were the most common biological causes of product recalls in the USA 2002-2023 (DeBeer et al, 2024).

A single recall can jeopardize the entire production and cause major financial damage.

Microbial Resistance

- Based on current scientific knowledge, the development of microbial resistance through the use of blue wavelengths or Spectral Blue MWHI® devices is neither known nor likely.

- Continuous disinfection reduces the possibility of cross-contamination, and the destruction of biofilms makes it more difficult for new colonies to form.

Warm, humid climates pose new challenges to the shelf life of food.

Molds

Molds can reduce the shelf life of many foods, by causing visible growth and producing toxins.

Spectral Blue used continuously in the production and storage areas can eliminate airborne and surface-dwelling molds to extend shelf life and reduce visible spoilage.

Spectral Blue MWHI® penetrates liquids, water and biofilms.

Biofilms

Biofilms can cause persistent contamination problems that are difficult to get rid of with traditional disinfection methods.

Spectral Blue MWHI® penetrates biofilms and destroys the microbial colonies within them.

Spectral Blue MWHI® thus reduces the risk of pathogens entering and spreading to different production areas.

Infection control on farms and fish farms

Animal diseases such as avian influenza, other viruses or molds can lead to disruptions in food production.

This prevents germs from being accidentally introduced and the stocks are better protected.

Learn more about the application of Spectral Blue MWHI® and practical examples.

Live Webinar: Wichtige Änderungen der ISO 22002-100: 2025

What quality managers need to know now

Learn about the changes brought about by the new standard and how to implement them in practice. You will also find out more about the latest research findings on food-borne pathogens.

Webinar Aufzeichnung: Spectral Blue MWHI® in der Lebensmittelbranche

Learn more about the use of blue light technology to prevent contamination in the food industry and how customers are using Spectral Blue™ to improve their disinfection processes and hygiene standards.

Testimonials

We are thrilled to be the first company in Switzerland to use Spectral Blue devices. By using Spectral Blue devices, we prevent cross-contamination in our production chain. We were able to define the optimum period of desinfection while considering also ecological and economic criteria. By using Spectral Blue, the growth and reproduction of unwanted microorganisms is prevented.

Metzgerei KünzliInformation and studies

Want to find out more?

Get to know the Spectral Blue MWHI® devices live and contact us for more information.

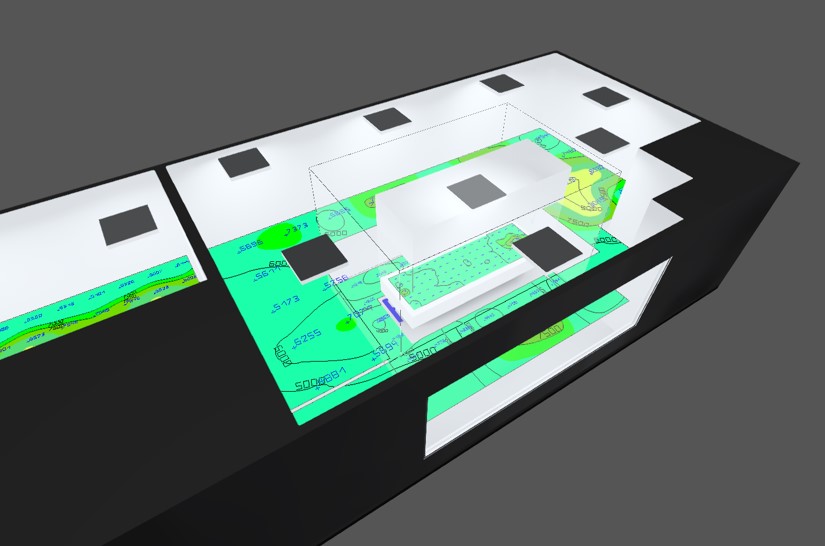

New! Receive a non-binding 3D plan tailored to your individual requirements – to the inquiry form.

„Spectral Blue is like a seatbelt in a car for us—you hope you'll never need it, but when it matters, it works reliably. “

Brüggli-Forellen Franz Georg Reichmuth, owner and managing director